Components: Parts Presentation and Handling

With the FlexiMate® Workstation, parts bins can be positioned or located anywhere on the workstation with two unique methods. The Flo-Thru Bars are typically used for high volume parts and the Bin Rails are used for slower movers or bulk type parts which are not kitted. Both provide gravity feed of parts to the front of the bins and minimize extended reaching, bending of the wrist and craning of the neck

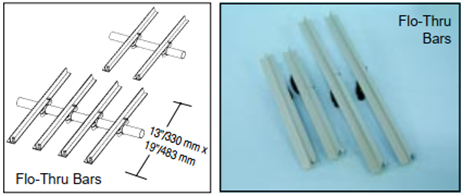

Flo-Thru Bar Assembly™

This unique “multi-bin” KanBan system will help reduce assembly stockouts! When the first bin is empty, remove it, and the second bin will slide into place. This also allows for multiple production changes without operator interruption through exact kitting. The empty bin signals the material handler to refill it, and the assembler can continue work. Use on both full and half-tiers (90012 & 90015). Two are required to support one bin box. Weight capacity is 25 lbs. between 2 bars.

| Length | Model No. | ESD Version |

|---|---|---|

| 19'/483 mm | 90030 | 95030 |

Bin Rail Assemblies

Use on both full and half-tiers (90012 & 90015) with molded plastic bins with lip on rear of bins. Weight capacity is between 24 lbs. (small) and 50 lbs. (large).

| Length | Model No. | ESD Version | |

|---|---|---|---|

| Samll Bin Rail | 22'/559 mm | 90031 | 95031 |

| Large Bin Rail | 40'/1016 mm | 90032 | 95032 |

Shelves

Use as additional work surfaces or to store parts bins, tooling, or documentation. Shelves are 14” deep and are made from aluminum sheet. Distributed weight capacity for the small shelf is 25 lbs. and 100 lbs. for the large. Shelves are mounted on universal fittings (90053).

| Length | ESD Version |

|---|---|

| 20'/470 mm | 90523 |

| 39'/1054 mm | 90524 |

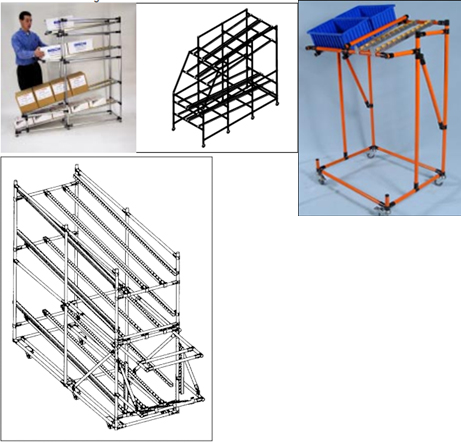

Custom Racking

Quixxsmart Structures® represents the latest engineering advances in a highly flexible, modular system of customized components needed for the creation of task specific flow racks and parts presentation carts. As a counterpart to our system, Quixxsmart specializes in designing and building cost-effective products that can dramatically improve your manufacturing output. Improved worker ergonomics and visual ergonomics are some of today’s goals in the industry. Reaching these goals should be simple, fast and cost effective. When your requirements include racks, workstations or structures, our product line has your solutions. Quixxsmart, an industry proven system in use worldwide, constructed from mechanical steel tubing and fittings. World class manufacturing. JIT material handling. Point of use parts presentations. Lean fixturing. Quick production changeovers. Sequenced parts delivery. Continuous improvement. For more information, please visit Quixxsmart.com.